Zinwi Biotech has strict testing standards to build a high-quality network of e-liquid

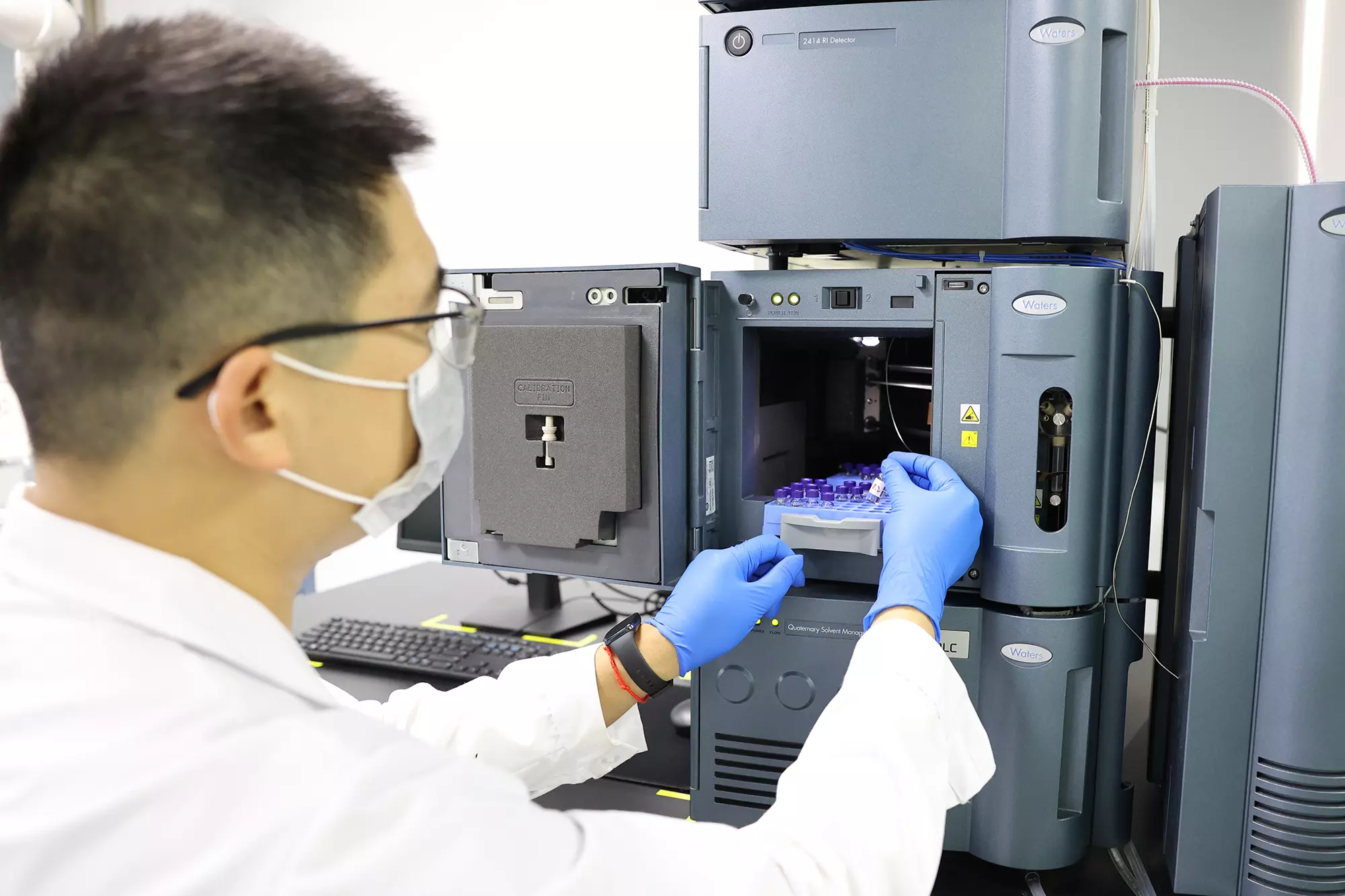

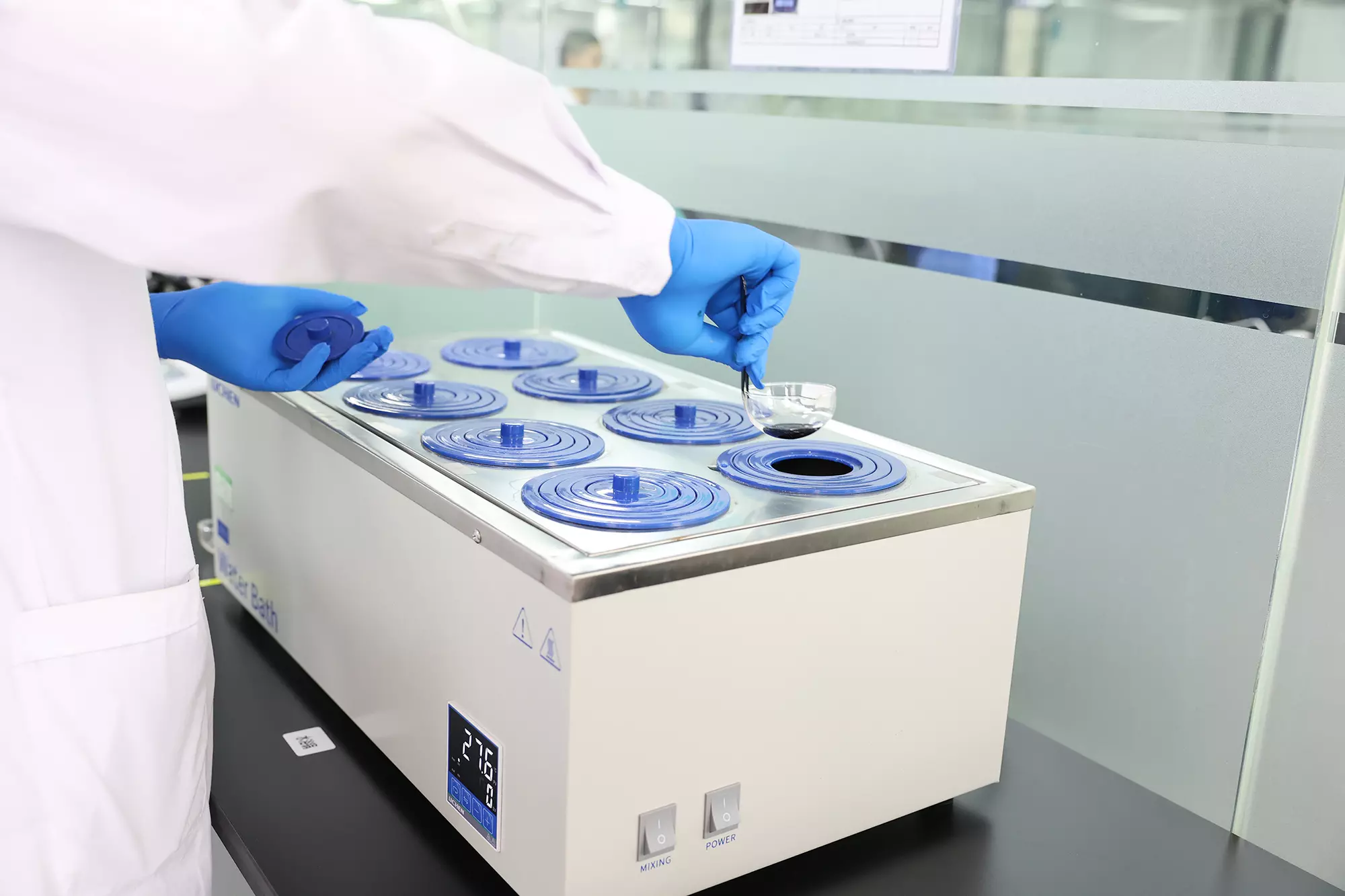

Adhering to the original intention of quality, boosting the development of the industry. Since its establishment, Zinwi's adherence to high-quality e-liquid has never changed. So far, Zinwi has not only built an advanced high-end testing instrument matrix and a scientific and efficient testing system, but also has a complete testing team and a standardized testing process.

Through the perfect sample collection, retention and traceability system, more than 50 testing standards have been established. From the inspection of raw materials to the inspection process of finished products, the whole process quality control from raw materials, production process to finished products is realized. When scientific and efficient testing standards and a huge instrument matrix complement each other, the development of high-quality nebulizers will flourish.

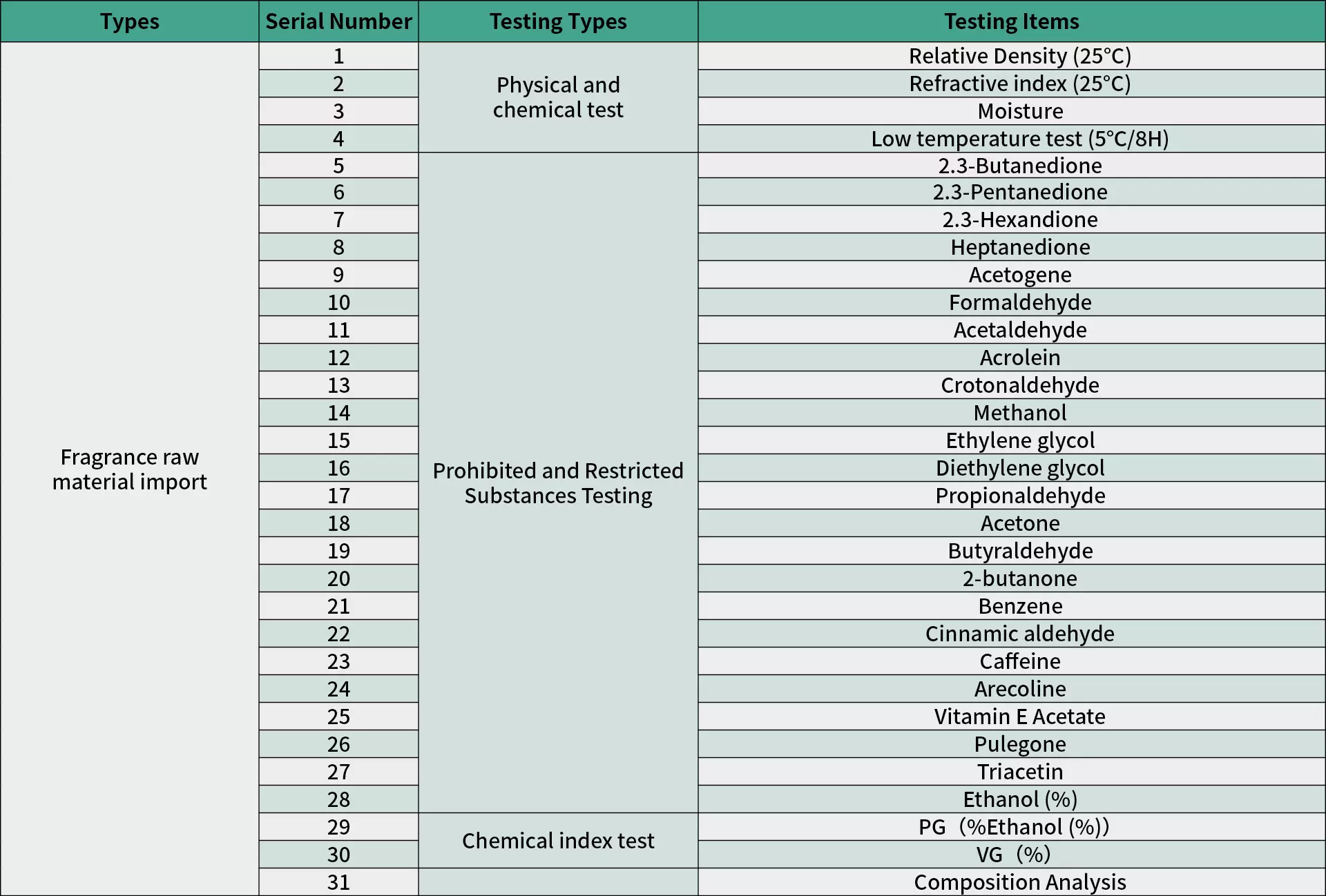

The first raw material import

In the first raw material import process, Zinwi carries out testing projects around four dimensions: physical and chemical testing, banned and restricted substance testing, chemical index testing, and compliance testing.

Prohibited and restricted substances testing is the key testing dimension of this link. Through the testing of prohibited and restricted substances in raw materials, pure and compliant raw material sources are guaranteed, laying a solid foundation for high-quality e-liquid.

The following is the toxicity analysis of prohibited and restricted substances:

2,3-Butanedione: It is mainly used in the preparation of cream essence and is the main raw material for the production of pyrazine fragrances, but it has reproductive and developmental toxicity.

2,3-Pentanedione: It has the aroma of sweet butter, cream and caramel, with a nutty undertone, the slightly sweet smell of quinone, and the diluted creamy smell, and it has respiratory toxicity.

2,3-Hexanedione: Has a sweet creamy, caramel, fruity odor, which has target organ toxicity.

Acetoin: It is mainly used in the preparation of food flavors such as cream, dairy products, yogurt and strawberries, which has respiratory toxicity.

Formaldehyde: At high temperature, the components of the e-liquid will undergo a cracking reaction, which may produce formaldehyde, which is carcinogenic and respiratory toxic.

Acetaldehyde: It can be used to blend fruit flavors such as oranges, oranges, apples, apricots, strawberries, etc. It can also be used in wine, rum, whiskey and other wine flavors. Carcinogenic and respiratory toxicity, but also addictive.

Acrolein: Acrolein is one of the harmful components in cigarettes, which can cause cell gene mutations and reduce the ability of cells to repair damage, which is the main factor that damages the retina.

Crotonaldehyde: also known as crotonaldehyde, has carcinogenicity, mutagenicity and target organ toxicity.

Methanol: Also known as hydroxymethane, methanol is toxic and will be oxidized into formaldehyde and formic acid (formic acid), which are more toxic than methanol, during human metabolism.

Ethylene glycol: used as a solvent, antifreeze, and raw material for synthetic polyester, with respiratory toxicity and reproductive development toxicity.

Diethylene glycol: present in tobacco leaves and smoke, has a spicy sweet taste, is toxic and irritating.

Propionaldehyde and butyraldehyde: Both are toxic substances that may exist in smoke, and have respiratory toxicity. Propionaldehyde also has cardiovascular toxicity.

2-Butanone: Also known as methyl ethyl ketone, it is mainly used in the preparation of cheese, coffee and banana flavors, and has respiratory toxicity.

Benzene: Benzene is the simplest aromatic hydrocarbon with a strong aromatic odor and is often used as a fragrance. It has carcinogenicity, cardiovascular toxicity and reproductive development toxicity.

Toluene: It has an aromatic smell similar to benzene and can be used in the production of fine chemicals such as spices. It has respiratory toxicity and reproductive development toxicity.

Ethylbenzene: It has an aromatic smell and is also used in the synthesis of fragrances. It is carcinogenic.

Benzaldehyde: Found in hyacinth, citronella, cinnamon, iris, and cistus, with bitter almond, cherry, and nutty aromas, it is toxic and respiratory irritating.

Cinnamaldehyde: commonly known as cinnamaldehyde, naturally present in essential oils such as Sri Lankan cinnamon oil, cinnamon oil, patchouli oil, hyacinth oil, and rose oil. It can be used in apple, cherry, and fruit flavors in food flavors. It is also a respiratory irritant.

Arecoline: It is addictive and carcinogenic.

Vitamin E acetate: used as an additive in medicines, nutrition, and cosmetics, and has respiratory toxicity.

Pulegone: It is mainly used for flavoring toothpaste, cosmetics and other daily chemical products, and can also be used to prepare artificial geranium oil, which is carcinogenic.

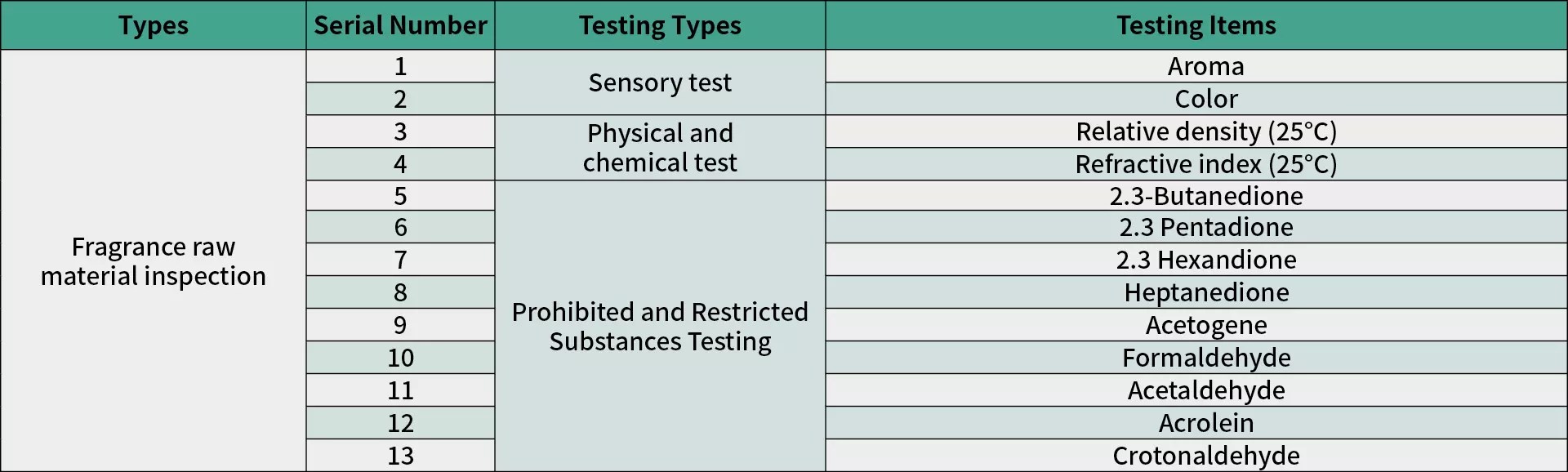

The second raw material import

In the second raw material import process, Zinwi carried out inspection projects around the three dimensions of sensory testing, physical and chemical testing, and testing of prohibited and restricted substances.

Among them, the sensory test must be approved by two fragrance smellers at the same time. The test results will be entered into the intelligent system, which is convenient for subsequent production and raw material tracking, and guarantees high-quality e-liquid in an all-round way.

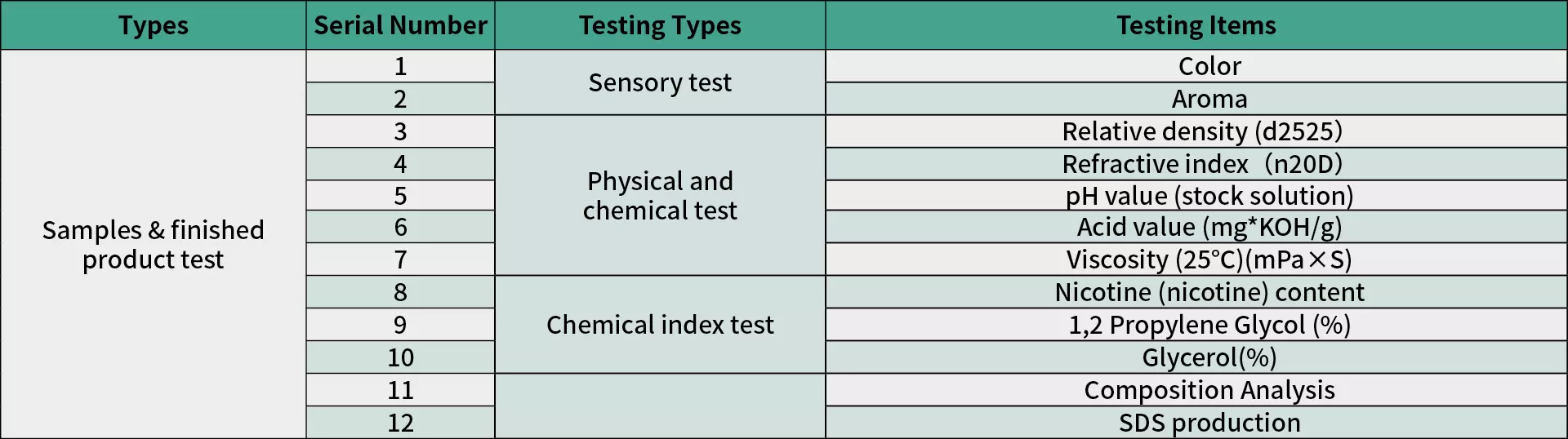

Finished product testing

Zinwi carries out the testing items of the finished e-liquid from the four dimensions of physical and chemical testing, flash point, chemical index testing, and compliance testing, and uses scientific and efficient testing methods to ensure the high quality and compliance of the e-liquid.

During the physical and chemical testing, the color, aroma and other indicators of the finished product are carried out. At the same time, 5 scent smellers conduct sensory evaluation. After the results are input into the intelligent system, the system will automatically judge whether it is qualified or not.

In the finished product test, the flash point test will also be focused on, which can measure the evaporation tendency of the substance and the stability after heating, and is an important indicator for the safety protection of the e-liquid product during transportation, storage and use.

In addition, in order to meet the restrictions on nicotine content in the new national standard, we will strictly conduct chemical index tests on the nicotine content in finished products to fully ensure product compliance. At the same time, carry out component analysis according to user needs, and issue COA component analysis report, SDS safety technical specification and other testing reports.

Zinwi has established a complete testing system from raw materials entering the factory to finished products leaving the factory through the establishment of testing standards for the whole process, and has fully realized the fine quality control of the e-liquid production process. At the same time, Zinwi has a scientific and efficient testing process, which can realize high-quality and high-efficiency supply of e-liquid to meet the customized needs of customers.

With the industry has developed rapidly, Zinwi is constantly facing new challenges, but the only thing that remains unchanged is the original intention of quality. On the road of globalization, Zinwi Biotech has continuously opened up a new development path for the e-liquid industry with quality. We are keeping "Driven by Innovation, Exploring the Future".

We will contact you as soon as possible