How ejuice is made?

Ejuice or vape juice is a liquid that is used in electronic vaporizers to produce various flavors and provide a satisfying vaping experience. The ejuice market has grown exponentially in recent years, with a wide range of flavors and options available to satisfy diverse vapers' needs. Ejuice is made up of distinct ingredients and goes through several production stages before it is bottled and made available to the consumer. In this essay, we will explore the process of making ejuice in no less than 1000 words.

The ingredients in Ejuice

One of the first steps in making ejuice is selecting the ingredients that will be used in its production. The primary ingredients used in ejuice include vegetable glycerin (VG), propylene glycol (PG), natural and artificial flavorings, and nicotine.

Vegetable glycerin (VG) is a natural ingredient derived from vegetable oils like coconut and soy. VG is widely used in ejuice and is considered the base of the ejuice. It is a thick and sweet substance that provides a smooth and satisfying hit and produces large vapor clouds.

Propylene glycol (PG) is a synthetic ingredient that is often used in food and pharmaceutical products. It is less viscous than VG and has a slightly sweet taste. PG is used in ejuice to carry flavorings and provide a throat hit.

Natural and artificial flavorings are added to ejuice to provide various flavor options. Natural flavorings are extracted from natural sources, whereas artificial flavorings are derived from synthetic sources. The flavorings used in ejuice range from fruit flavors to candy flavors, and even tobacco and menthol flavors.

Nicotine is an optional ingredient in ejuice that provides the vaper with a nicotine hit, similar to that provided by traditional tobacco cigarettes. The amount of nicotine added to ejuice varies depending on the strength chosen by the vaper.

The production process of Ejuice

After selecting the ingredients, the next step in making ejuice is mixing the ingredients. Mixing is a crucial step that determines the flavor, nicotine strength, and physical properties of the ejuice.

There are two main methods of mixing ejuice, namely batch mixing and continuous mixing. Batch mixing involves mixing large quantities of ejuice in a single batch, while continuous mixing involves mixing ejuice in a continuous flow process.

Batch mixing involves combining the VG, PG, and nicotine (if included) to create a base liquid that is then fortified with natural and artificial flavorings. The mixing process aims to create a consistent flavor profile and desired nicotine strength. During mixing, the ingredients are added in specific proportions to ensure the flavor, nicotine strength, and viscosity are maintained.

Continuous mixing is a newer method of mixing ejuice that uses advanced technology to create a consistent product. In continuous mixing, the ingredients are added to a machine that continuously mixes the ejuice while refining the flavors, nicotine strength, and physical properties of the ejuice.

After mixing, the ejuice is left to steep for a few days or weeks. Steeping is a crucial process that allows the flavorings to blend, resulting in a more distinct and nuanced flavor profile. During steeping, the ejuice is left in a cool, dark place to allow the natural and artificial flavorings to infuse and blend.

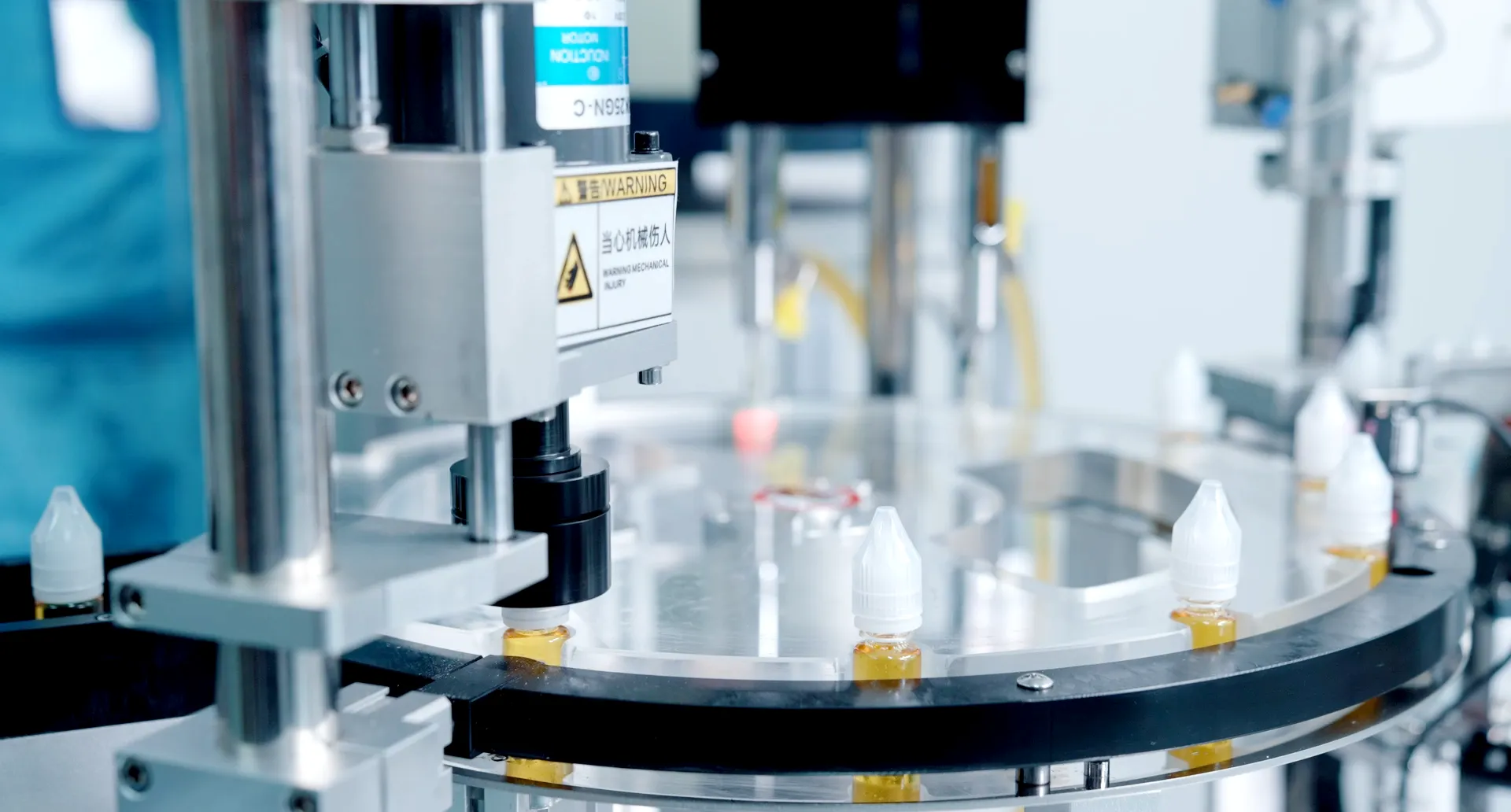

The final process in ejuice production is bottling and packaging. The ejuice is bottled in a sterile environment to prevent contamination and ensure optimal freshness. The packaging process involves labeling the bottles, including the nicotine strength and flavor, packaging the bottles in boxes, and shipping them to distributors, wholesalers, and retailers.

Safety Considerations in Ejuice Production

Ejuice production requires strict adherence to safety considerations to ensure the production of a safe and high-quality product. The ingredients used in ejuice production can be hazardous if not handled correctly, and adequate health and safety measures must be in place.

Ejuice manufacturers must comply with strict standards and regulations, including Good Manufacturing Practice (GMP) requirements and compliance with US Food and Drug Administration (FDA) regulations. Compliance with these standards ensures the production of high-quality ejuice that meets the required safety standards for consumption.

Ejuice production involves several stages, including ingredient selection, mixing, steeping, and bottling. The final product produced is a liquid that provides a satisfying vaping experience. The ingredients used in ejuice production include VG, PG, natural and artificial flavorings, and nicotine. These ingredients are mixed in specific ratios to create a consistent and appealing flavor profile.

Safety considerations are crucial in ejuice production, and manufacturers must comply with strict standards and regulations to ensure the production of a safe and high-quality product. The ejuice market has grown significantly, and the demand for innovative and exciting flavors continues to increase. Ejuice manufacturers must continue to meet the vapers' preferences and deliver high-quality products that meet safety standards.

We will contact you as soon as possible