Zinwi Bio: Solving the Challenges of High-Volume E-cigarette Flavor Delivery

High-volume e-cigarettes have gained popularity due to their rich vaping experience and excellent value for money. However, the rapid market growth has revealed several technical challenges, including bitterness, burnt coils, and flavor degradation. These issues impact the consumer experience and present significant innovation hurdles for brands.

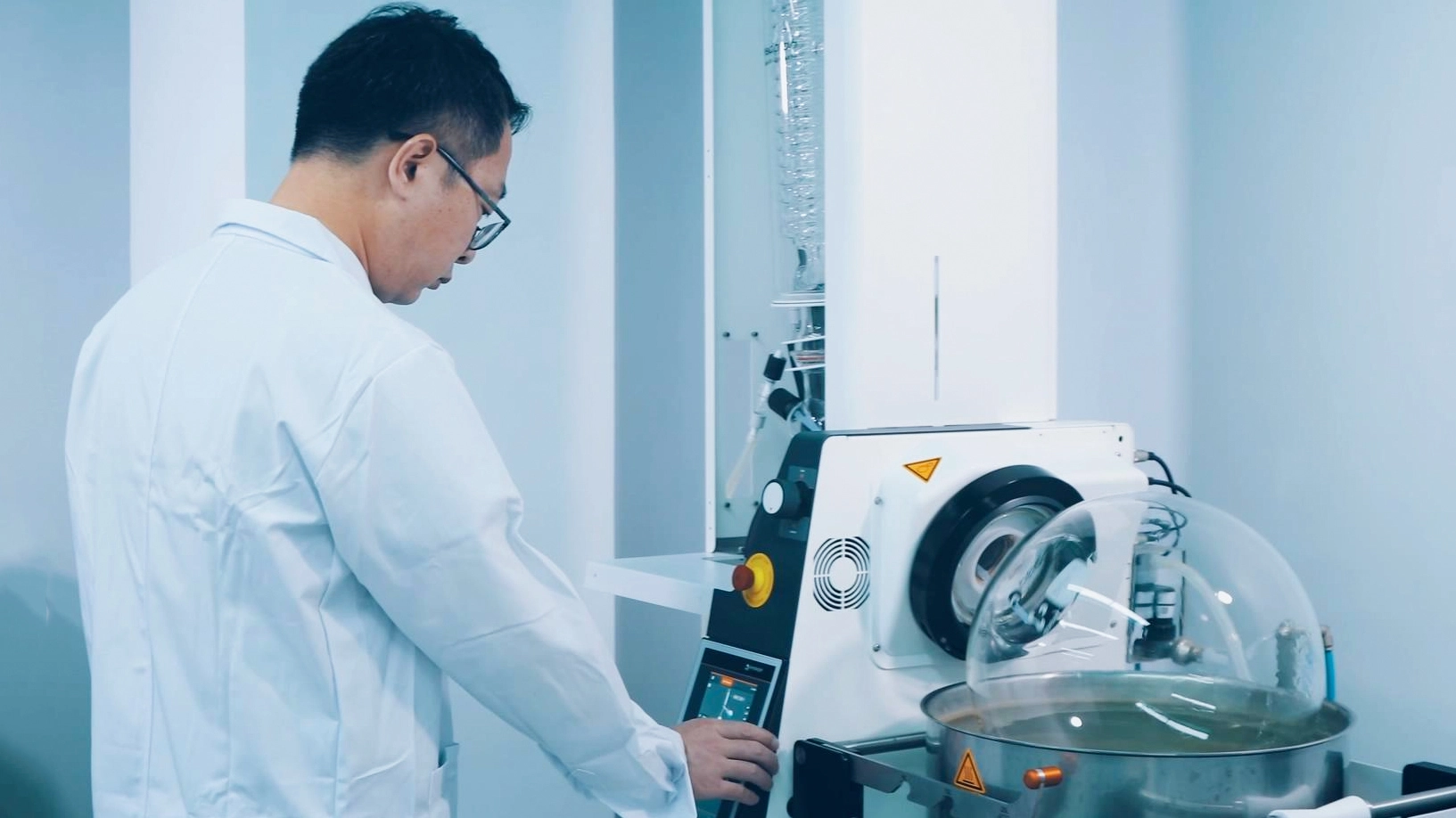

Zinwi Bio has made significant strides in addressing these critical issues through in-depth research into e-liquid formulations, tobacco extracts, and device compatibility. Leveraging three years of dedicated research at the Zinwi Yunnan Research Institute in tobacco extracts, we have not only overcome numerous technical challenges but also customized high-quality, flavorful e-liquids to meet market demands.

I. Optimized Formulations and Processes: Addressing Core Pain Points

Improved Flowability, Reduced Residue

High e-liquid residue is a common frustration for users of high-volume e-cigarettes. Zinwi has adjusted e-liquid formulations to enhance flowability and, in conjunction with optimizing the density and pore structure of the wicking material, significantly reduced e-liquid residue. This ensures that every drop of e-liquid is utilized efficiently, providing users with a consistent and long-lasting vaping experience.

Enhanced Taste Profile, Eliminating Bitterness and Aftertaste: Consistent flavor is crucial for successful e-cigarette products. To address the common issues of aftertaste and bitterness in high-volume e-cigarettes, Zinwi has selected appropriate sweeteners and adjusted the ratio of sweeteners to other flavoring agents to improve the overall taste profile. Simultaneously, by processing the bitter components of natural extracts, we have effectively reduced bitterness, providing users with a smoother vaping experience.

Fine-Tuned Formulation, Solving Poor E-liquid Delivery

Poor e-liquid delivery leading to inconsistent vaping is another major pain point. By adjusting the ratio of components in the e-liquid formulation, we have significantly improved flowability and e-liquid delivery, ensuring rapid transport to the heating element for consistent and smooth vaping.

II. Technological Innovation and Device Matching: Ensuring a High-Quality Experience

Coil Carbonization Control, Reduced Odor

Coil carbonization not only affects taste but also leads to unpleasant odors. Zinwi employs innovative raw material processing techniques to reduce the proportion of carbon-based substances from the source. For instance, we remove and reprocess large molecules prone to coil carbonization from raw materials, significantly reducing the likelihood of carbon buildup. Furthermore, by selecting different types of tobacco extracts and optimizing extraction and secondary processing techniques, we have developed e-liquid formulations suitable for different devices, significantly reducing unpleasant odors and ensuring consumers enjoy a purer vaping experience.

Delayed Flavor Degradation, Improved Stability

To address flavor degradation during shelf life and use, we have optimized the combination of fixatives and flavoring agents in our formulations. We also provide professional storage recommendations to help brands optimize warehouse management and ensure product freshness. For high-volume e-cigarettes, we recommend optimizing the reservoir design, dividing the reservoir into multiple smaller compartments to minimize the volume of e-liquid exposed to air during use, promoting a "take-as-needed" approach with remaining e-liquid sealed to preserve freshness and minimize air circulation, thereby delaying flavor loss. Additionally, inherent flavor characteristics play a role; citrus and cola flavors, for example, tend to degrade faster than others. Brands should minimize the shelf life of these flavors and prioritize delivering fresh batches to consumers.

Device Compatibility and Flavor Diversity

Zinwi focuses not only on compatibility with individual devices but also on market demand, adjusting e-liquid formulations according to different coil structures and heating methods. Extensive CNAS laboratory test data guides our exploration of optimal pairings between various brands of devices and e-liquids, ensuring perfect flavor profiles across different devices. Furthermore, we continuously innovate flavors to match market trends, launching products that comply with global regulations and consumer preferences.

III. Forward-Looking Development

High-Efficiency R&D, Innovation-Driven

Zinwi's comprehensive R&D system enables efficient resource integration and rapid response to market changes. Cross-departmental teamwork ensures we remain at the forefront of flavor development, continuously launching new products that meet market trends.

Customizable Solutions, Flexible Response

Our mature customer service system allows for customized e-liquid flavors tailored to specific client needs. This flexibility enables us to provide globally compliant products while meeting diverse market demands, enhancing our clients' brand competitiveness.

Zinwi Bio's continued technological innovation and keen market insight have not only addressed multiple pain points but also cultivated a diverse range of flavorful options, providing customized e-liquid solutions for global clients. We believe that through collaboration with brands, we can create a more comfortable and enjoyable vaping experience for consumers, driving industry development and progress.

We will contact you as soon as possible