Zinwi Bio’s Smart Manufacturing Upgrade: Powering Brands with a More Efficient, Reliable E-Liquid Supply Chain

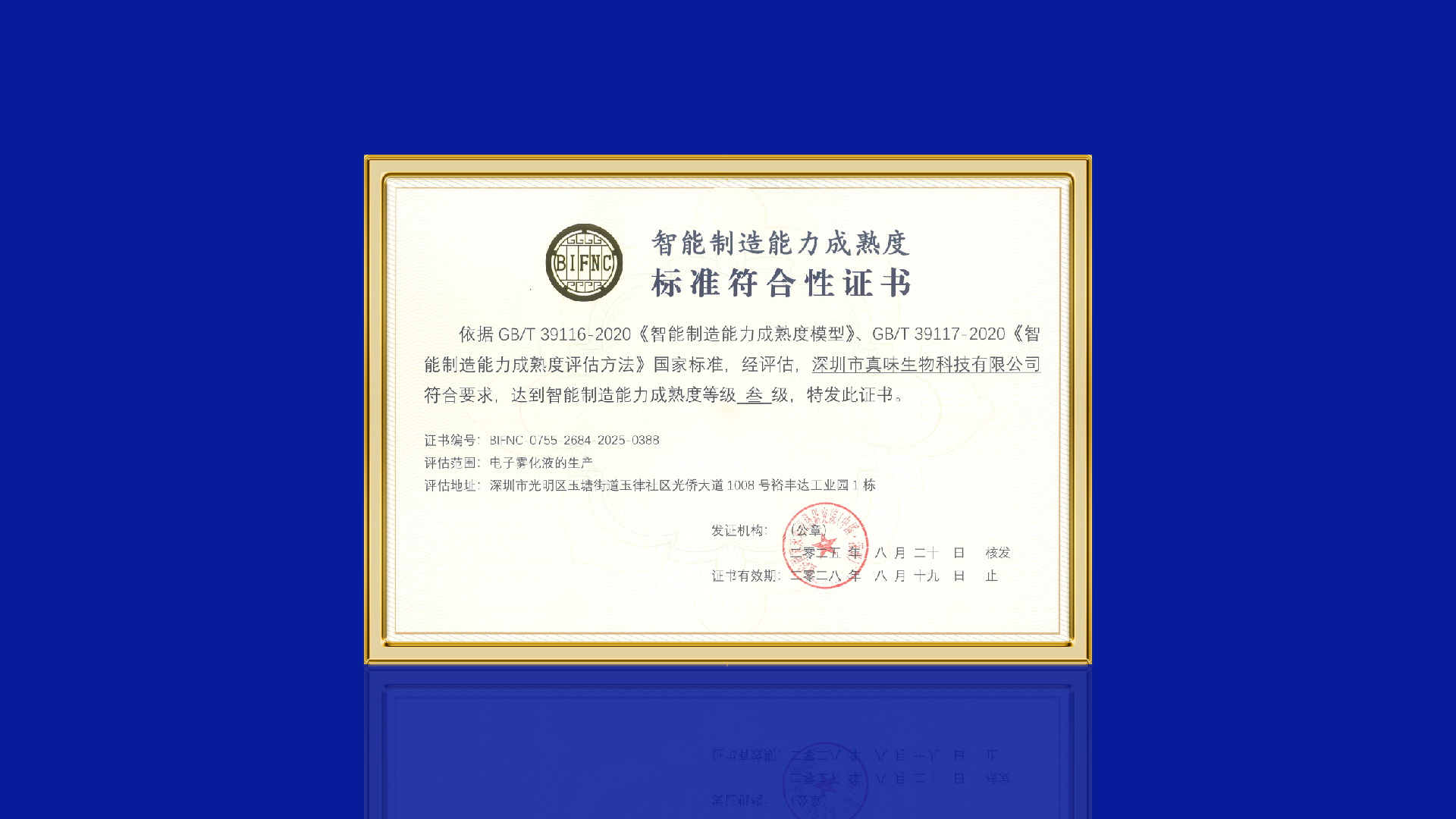

As manufacturing undergoes deep digital transformation, smart capabilities have evolved from boosting in-plant efficiency to becoming a core driver of supply chain collaboration. We are proud to announce that after strict evaluation, Zinwi Bio has officially earned the Smart Manufacturing Capability Maturity Level 3 Certification—a leap from "systematic management" to "high-level integration." This milestone enables end-to-end data connectivity and intelligent optimization across R&D, production, quality control, and supply chain coordination.

From Level 2 to Level 3: Moving from Informatization to Integration, Making Smart Manufacturing "More Customer-Centric"

As early as when Zinwi Bio obtained the Level 2 Smart Manufacturing Capability Certificate, we had already laid a solid foundation in equipment automation and production informatization. Through the development of the MES (Manufacturing Execution System), ERP (Enterprise Resource Planning) system, and quality traceability platform, we achieved automated control and data collection of key equipment, laying the groundwork for standardized production and traceable management.

After successfully upgrading to Level 3 (Integration) this time, Zinwi has built a system integration framework covering three levels: enterprise operation, management, and equipment management. This framework enables data communication between equipment and systems, as well as between systems themselves, further achieving in-depth data integration across production, management, and supply chain systems. Ultimately, it establishes a digital management system for the entire R&D, production, quality, and logistics processes, empowering customers’customized product R&D through timely information sharing and dynamic optimization.

In simple terms, every step—from e-liquid formula development and order scheduling to raw material procurement and quality approval—can be efficiently coordinated within the same data chain.

What Does This "Upgrade" Mean for Customers?

For B2B customers worldwide, this is not just a level upgrade, but a set of smart solutions that truly delivers competitive advantages. This upgrade means faster new product response, more stable quality, smoother communication, and more reliable delivery for you.

Whether it is new product testing, flavor adjustment, or mass production, we can respond in a shorter time, helping you accelerate the process from idea to market launch. The raw material source, formula parameters, and production environment of every drop of e-liquid are clearly traceable throughout the entire process. Meanwhile, the data-driven production planning and scheduling mechanism ensures more reliable delivery and more efficient cooperation.

1. Faster Order Response Speed

The e-cigarette market changes rapidly, and brand customers have increasingly higher demands for shorter new product cycles. With the completion of the Level 3 smart manufacturing system, we have achieved full-link business system and data integration, enabling efficient connection from customer needs to delivery:

Shorter new formula testing cycles;

Significantly improved sample delivery efficiency;

Reduced order response time.

When you put forward customized requirements, your needs can be directly transmitted to the R&D and production departments in real time. Our system can instantly display current production capacity and raw material inventory, support the development of R&D, production plans, and testing tasks, greatly reducing manual scheduling and communication links. This enables rapid production scheduling, shortens delivery cycles, and helps customers' products enter the market faster.

2. Higher Quality and Stability

Quality stability has always been a core concern for B2B brands. With the establishment of the Level 3 smart manufacturing system, we use big data algorithms to monitor and analyze production data. By conducting real-time monitoring of equipment parameters and production data throughout the production process, we can achieve "real-time process quality monitoring + automatic abnormality early warning". Key process parameters are monitored during the entire e-liquid mixing, filling, and packaging processes to ensure consistent flavor and performance across different batches. Instead of relying solely on post-batch testing to identify issues, we now prevent problems during the process control stage.

3. Enhanced Traceability and Compliance Certification Capabilities

To meet the regulatory requirements of export markets and different regions, our production traceability system records the entire life cycle of each batch. Every drop of e-liquid can be traced back to its raw material batch number, production time, operator, and inspection results. This not only enhances your ability to submit documents for product compliance but also provides strong support for subsequent regulatory sampling inspections and quality appeals.

4. Smoother Collaboration

The new Level 3 system breaks down barriers between R&D, production, quality control, and customer service. Information such as your formula changes, parameter revisions, and testing feedback can be synchronized to all relevant links in real time, reducing human delays and communication costs. Your project specialist can directly view progress milestones through a visual interface, ensuring more transparent customization and more reliable cooperation.

We have upgraded from providing "high-quality e-liquid" to offering "high-quality e-liquid + fast speed + full transparency". This ensures that every creative flavor of yours can be turned into reality faster, more stably, and more safely.

More Importantly, We Can Help You Go Further!

Smart manufacturing not only enhances our internal capabilities but also provides a platform for joint growth with our customers and partners. Through data interconnection and system integration, we can help brand owners in the following ways:

Jointly build an R&D database: In the future, we may open part of the process data to collaborate with customers on developing flavor adjustment and performance optimization models, improving the success rate of sample development.

Support lean supply chains: In the future, we may share forecasting data and inventory status to achieve demand linkage and production capacity adjustment, helping customers optimize their inventory structure.

Participate in forward-looking projects: As an industry-leading smart e-liquid manufacturer, we may cooperate with brand owners to develop adaptive flavor-mixing systems in the future, making flavor innovation more efficient.

These capabilities make us more than just a supplier—we are your partner on the path of digital innovation.

Looking to the Future: Smart Manufacturing Drives More Creative Collaboration

The e-cigarette industry is in a period of rapid adjustment. In such an era, a stable, efficient, and transparent manufacturing partner represents a dual guarantee of cost advantages and innovation advantages. Zinwi Bio will continue to invest in process intelligence, testing automation, and data security, and gradually move towards Smart Manufacturing Capability Level 4. This will enable a higher level of self-optimization and autonomous prediction, providing you with an even better customized experience.

We believe that the future of the industry is not just about "manufacturing better e-liquids", but about "using intelligence to deliver high-quality e-liquids to brand markets around the world faster".

Thank you for your consistent trust and cooperation. Let us work together on this higher-level smart manufacturing platform to create the next stage of growth and breakthroughs!

We will contact you as soon as possible