The storage history of a drop of e-liquid——Zinwi Biotech upgraded the intelligent storage system

At the beginning of the new year, let us focus on the storage journey of a drop of e-liquid, pay attention to the essence of storage, focus on the intelligent storage system of Zinwi Biotech from the source of production, and explore how to use an efficient and safe storage system to escort the flavor manufacturing.

Partitioned storage, integrated with business processes

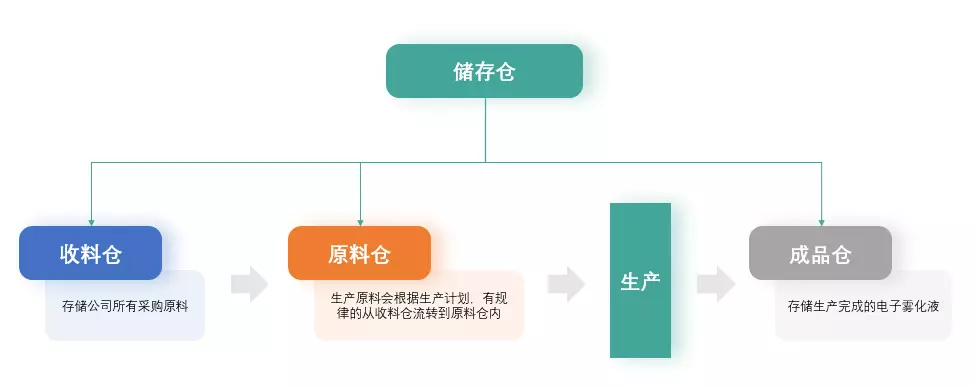

In order to standardize the storage of various materials, Zinwi Biotech manages the storage in separate warehouses and partitions. First, Zinwi Biotech integrates the warehousing link with the quality inspection, manufacturing, and other associations, integrates with the company's business process, and divides the warehouse into three parts: the receiving warehouse, the raw material warehouse, and the finished product warehouse.

The receiving warehouse mainly stores all the raw materials. It is the first stop for raw materials entering the company's production line, and it is also the storage warehouse with the largest area and the most reserves in the entire storage process. All raw materials will go through strict quality inspections, and will only be put into storage after passing the test.

The raw material warehouse is the downstream link of the receiving warehouse. All qualified production raw materials will flow regularly from the receiving warehouse to the raw material warehouse according to the production plan. This is the transfer site before the production of e-liquid, and only the raw materials that pass through the raw material warehouse can enter the production workshop.

The finished product warehouse is mainly used to store the finished e-liquid. This is the key process before the delivery of e-liquid, the bridge connecting the production line and the logistics system, and the finished product warehouse with the largest and busiest daily turnover. The e-liquid will undergo the final quality inspection here to ensure the stability and safety of the quality.

Zinwi Biotech also conducts partition management within the same storage warehouse. For example, the entire receiving warehouse is divided into areas such as incoming material area, turnover area, inspection area, defective product area, and qualified raw material area. Different areas have strict access and exit conditions. Clear regional division can not only ensure the accuracy of storage but also effectively improve the quality of raw materials and final products.

The intelligent system enables efficient circulation of warehousing

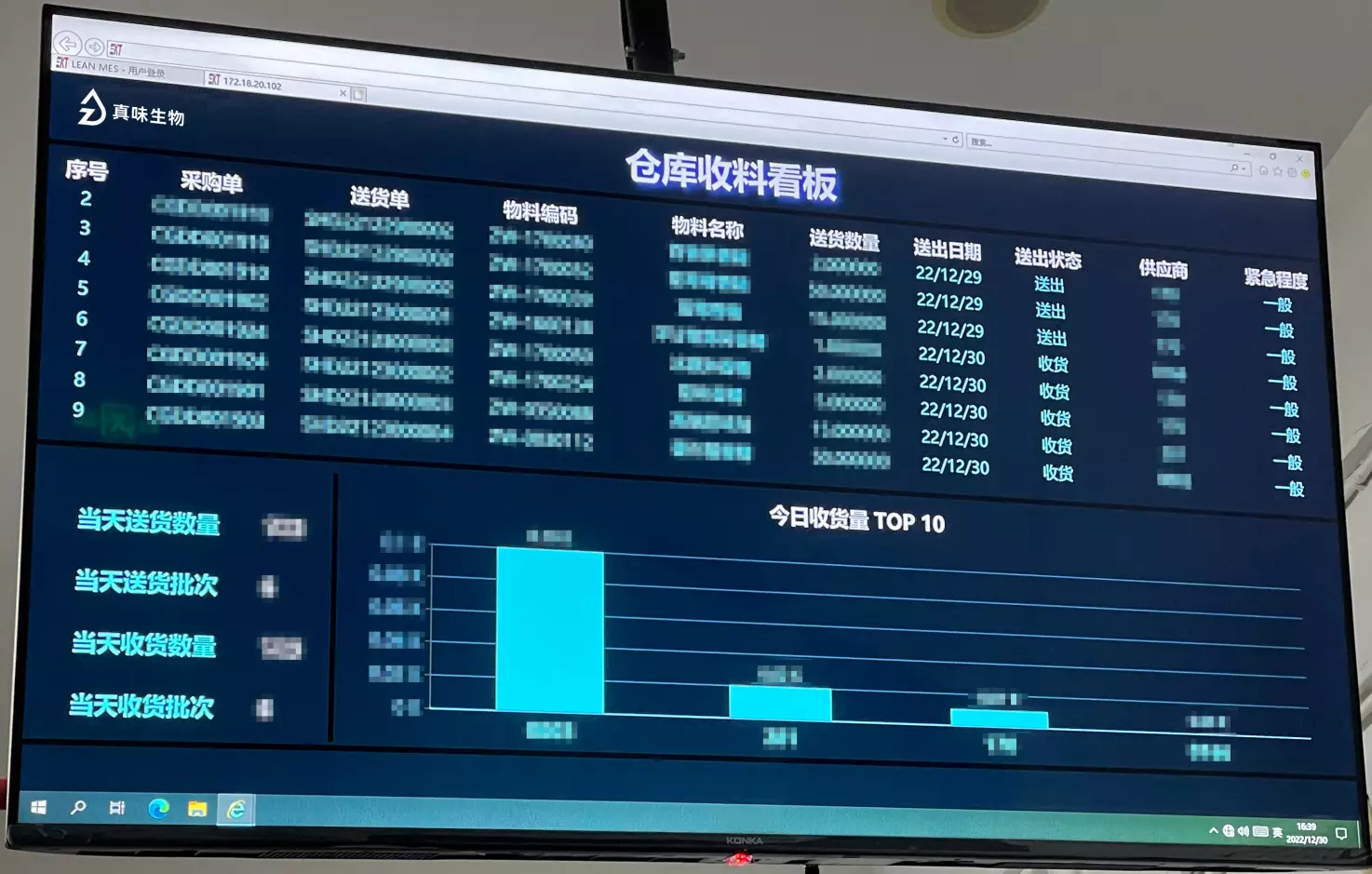

The intelligent management system fundamentally guarantees the efficient circulation and docking of warehousing. In order to ensure the accuracy of warehousing, Zinwi Biotech has established an intelligent information system, from the receiving warehouse, to the raw material warehouse, and the finished product warehouse, and uses the information platform to run through the entire storage process.

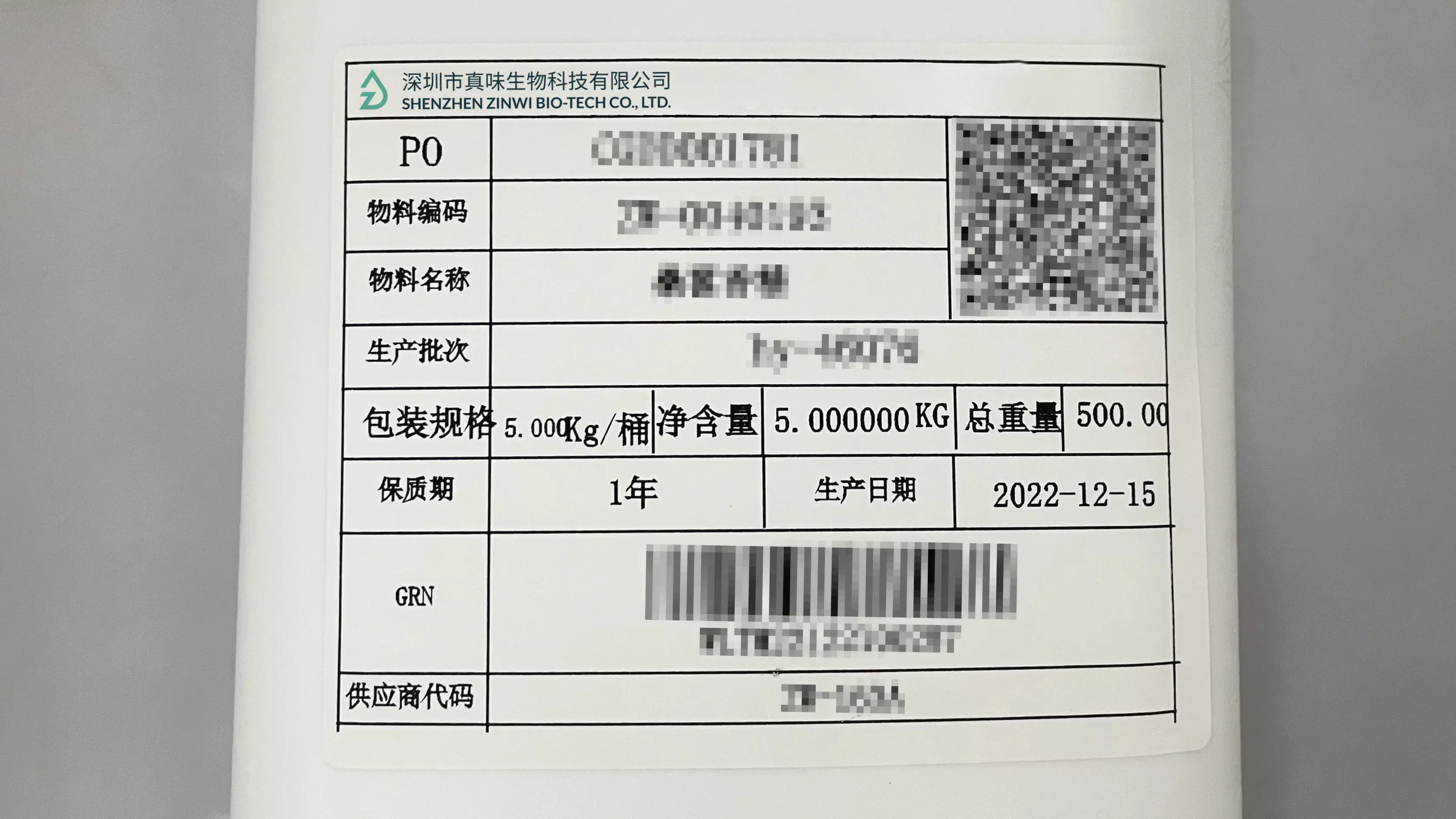

From the moment the raw materials enter the factory, Zinwi Biotech has established a smart label system and set up a GRN code for each raw material. Through the wide application of the labeling system, the existing dynamics of each raw material can be tracked in real-time. The smart large screen in the storage warehouse can clearly reflect the name, quantity, status, and supplier information of each raw material. The intelligent warehouse management system can perform operations such as inbound and outbound, warehouse transfer, inventory, and review of the receiving warehouse and raw material warehouse to ensure the integrity, correctness, and FIFO of raw material storage.

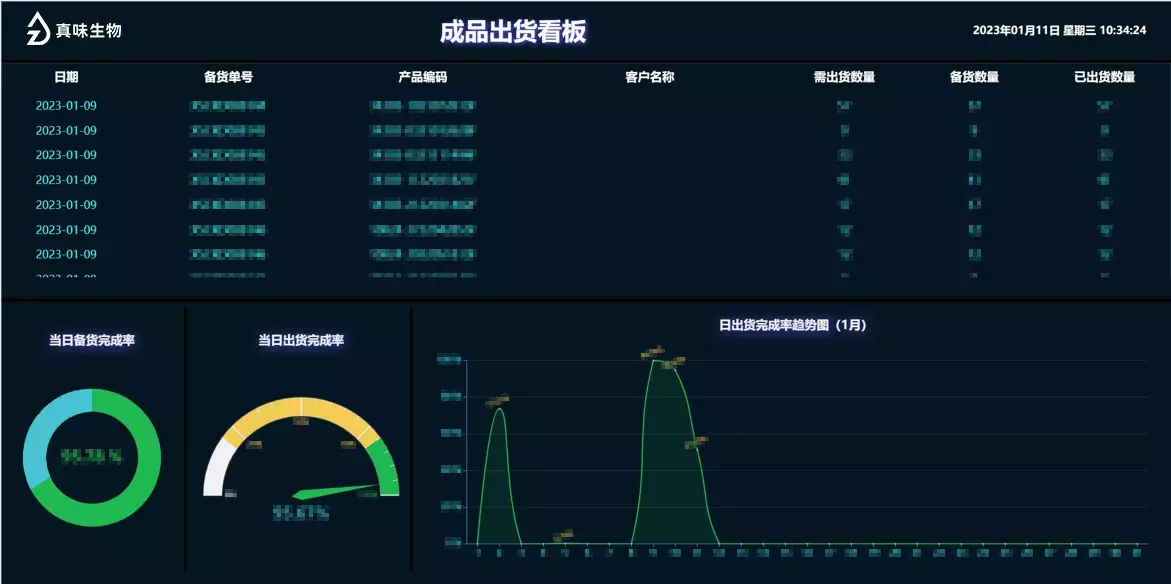

Inside the finished product warehouse, the application of intelligent systems is still very efficient. Each finished product warehouse has its own code, which matches the stored product information, enabling one-click query and fast delivery. At the same time, the goods in the finished product warehouse have an exclusive labeling system, which can distinguish product information and storage time, and facilitate product inventory and quality re-inspection. The internal large-screen system can reflect the production volume and daily shipment volume in real time, ensuring the efficient flow of goods.

Safety management provides a guarantee for production

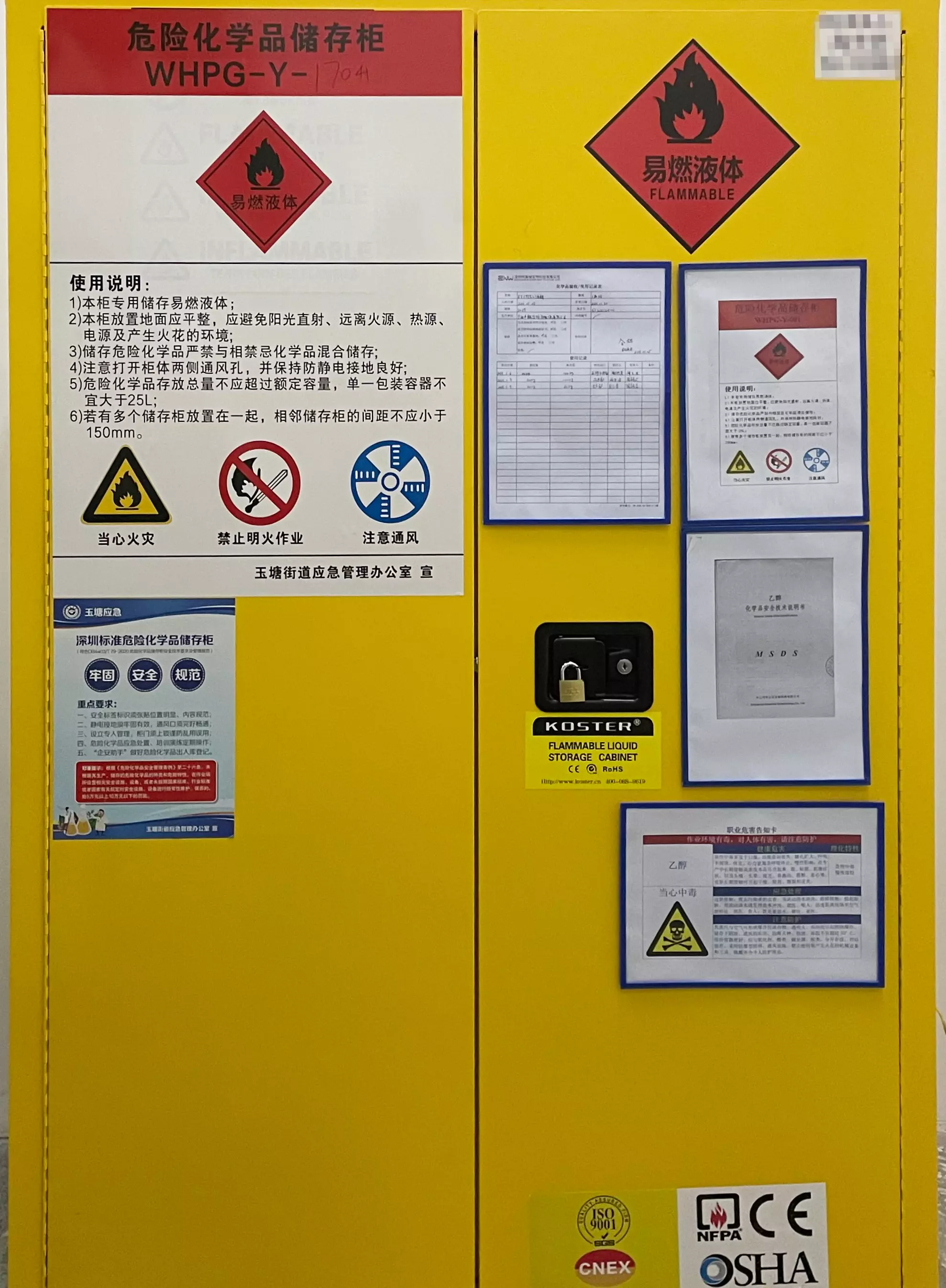

Zinwi Biotech has established a standard storage environment for raw materials and products and selects the most suitable storage conditions according to the chemical properties and material characteristics of different goods to ensure the stability of various raw materials and products. At the same time, in order to meet safety standards, the hazardous chemical intermediate warehouse and hazardous chemical storage warehouse are set up. The warehouses are equipped with various security systems, fire-fighting facilities, and emergency handling standards to ensure the safety of the storage link from the source.

In the raw material storage area in the receiving warehouse, each raw material has a matching material safety data sheet. The form not only covers complete raw material information records but also assists warehouse managers in identifying potential hazards of raw materials and various emergency response plans, ensuring the safety of personnel and raw materials.

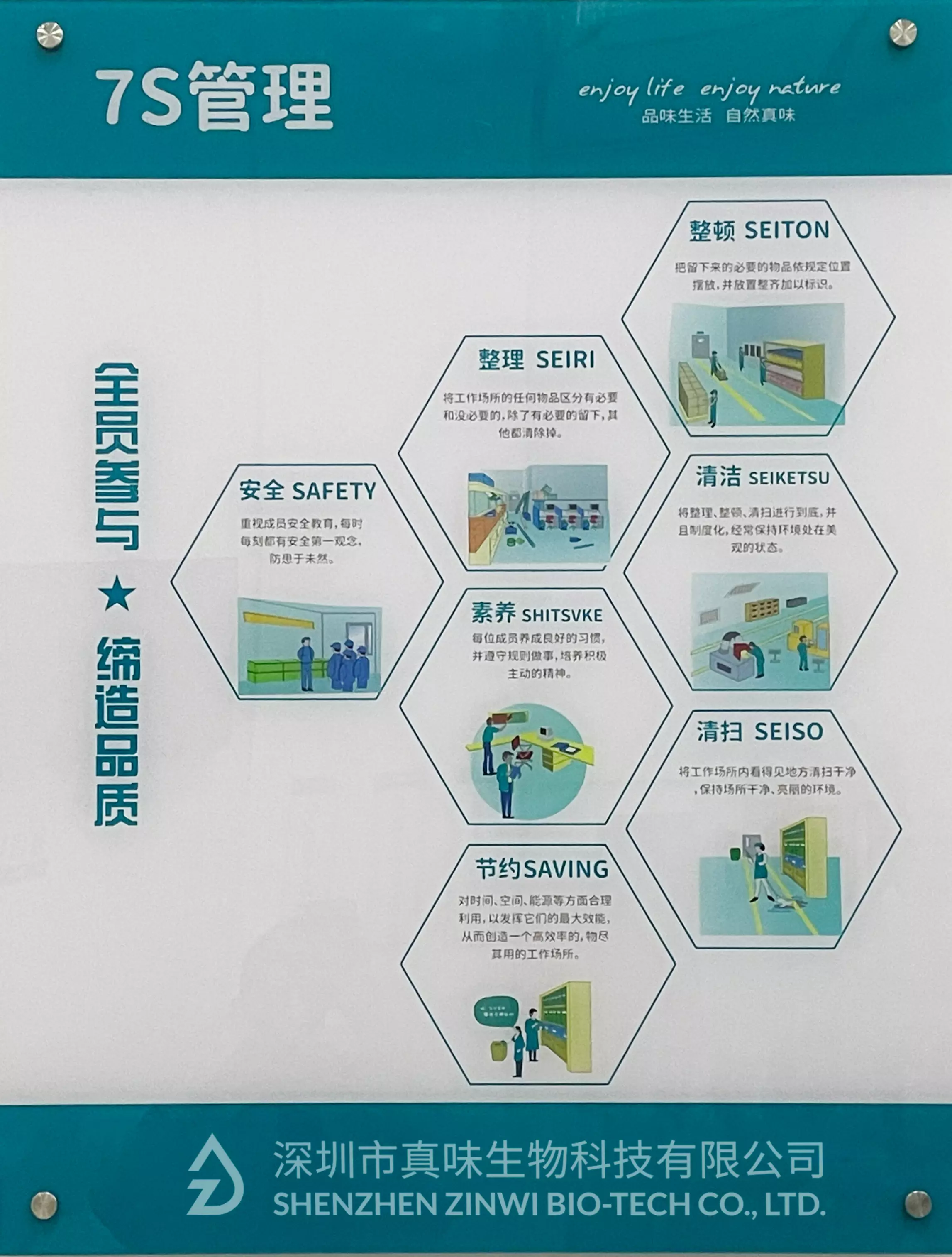

At the same time, Zinwi Biotech has established a 7S safety management system in all storage warehouses, starting from safety, sorting, rectification, quality, cleaning, saving, and cleaning, and realized the safety management standards of storage warehouses. It can not only ensure the cleanliness and standardization of the storage environment but also effectively improve the safety factor of the storage link through the safety system. With the practice of full participation in the safety management of Zinwi Biotech, we will provide high-quality e-liquid solutions.

This is the warehousing process of a drop of e-liquid, and it is also the process of Zinwi Biotech’s continuous fulfillment of the company's mission and leading the development of the industry. Whether it is zoning warehouse management, an intelligent warehouse management system, or various safety measures, all of them reflect the attention of Zinwi Biotech to storage and quality.

Zinwi Biotech pays attention to the storage link, lays the quality foundation of e-liquid products with storage safety, and realizes the high standard requirements of e-liquid with storage standards.

We will contact you as soon as possible