Zinwi Biotech obtains CMMM® Level 2 certification for intelligent manufacturing capability, competing in the new field of intelligent manufacturing

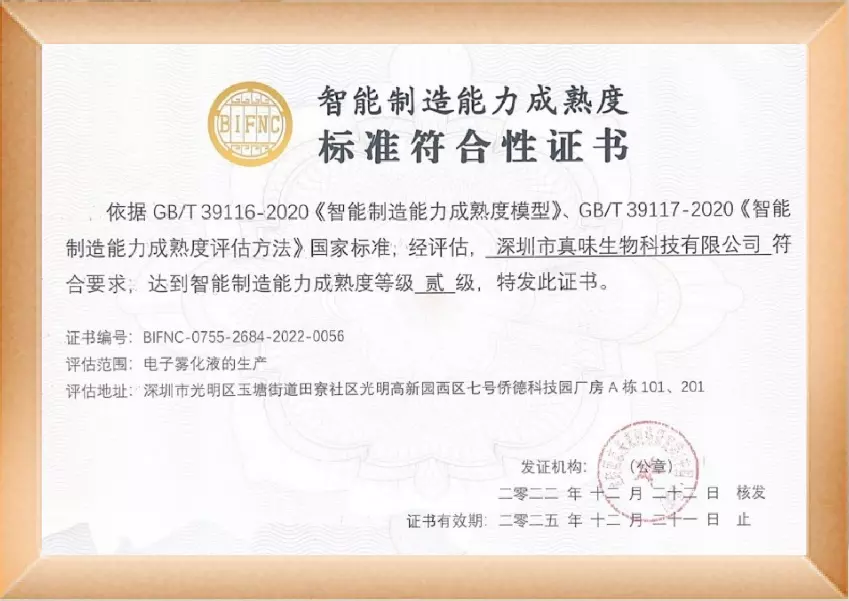

Recently, Zinwi Biotech has passed the CMMM® Level 2 certification for intelligent manufacturing capability. With remarkable results in lean management and digital transformation, Zinwi Biotech has entered a new era of intelligent development.

I. The Capability Maturity Model for Intelligent Manufacturing (CMMM®) Evaluation

The CMMM® evaluation is based on two national standards, "Intelligent Manufacturing Capability Maturity Model" (GB/T 39116-2020) and "Intelligent Manufacturing Capability Maturity Assessment Method" (GB/T 39117-2020). It assesses the overall level of intelligent manufacturing development in enterprises, helps them identify their weaknesses and shortcomings in the development process, and determines the direction for improving intelligent manufacturing capability.

The intelligent manufacturing capability maturity model describes the ladder goals and evolution path that enterprises need to achieve in implementing intelligent manufacturing. It proposes the core elements, features, and requirements for achieving intelligent manufacturing, and comprehensively evaluates the development level of digitalization, networking, and intelligentization of enterprises from five maturity levels of personnel, technology, resources, and manufacturing. The five levels are: Level 1: Process-oriented management (planning level), Level 2: Digital transformation (standard level), Level 3: Networked integration (integration level), Level 4: Intelligent production (optimization level), and Level 5: Innovation in the industrial chain (leading level).

According to the "Intelligent Manufacturing Development Index Report (2021)," currently 69% of Chinese manufacturing enterprises are at Level 1 or below. Manufacturing enterprises that have reached Level 2 and Level 3 account for 15% and 7%, respectively, and those that have reached Level 4 or above account for 9%. The highest level of intelligent manufacturing capability in China is Level 4, and there are no enterprises in the country that have passed Level 5 certification.

II. Intelligent Manufacturing Empowers Zinwi Biotech for High-Quality Development

Since its establishment, Zinwi Biotech has always grasped the development direction of the e-liquid industry, continuously exploring new modes of intelligent manufacturing while driving enterprise development through innovation. It insists on using advanced production processes and intelligent equipment, and through digital and intelligent management, it creates high-quality and high-standard solutions for e-liquid.

Integrated information management system.

Zinwi Biotech connects its proprietary production network to processing equipment and uses PDAs to collect real-time data, uploading various types of data to the information management system. Based on system data and human experience, data analysis is carried out to meet specific data usage requirements, achieving real-time sharing of data and information.

To fully achieve digital and lean management, Zinwi Biotech actively carries out system integration planning and construction, achieving integration between key business activities, equipment, and systems, and establishing an integrated digital platform for business interconnection and communication. This effectively enhances the process control ability of various business processes, promoting the company's development and improving efficiency and quality.

Information production and manufacturing system.

Zinwi Biotech uses automation technology and information means to transform and standardize the core production links of e-liquid, achieving data sharing in the production and manufacturing process. By applying automation technology and various information management systems, production and operation processes are standardized, traditional production methods are changed, e-liquid quality and automation production efficiency are improved, and the production organization process is standardized and orderly.

Intelligent warehousing management system.

Zinwi Biotech improves the construction of intelligent warehousing management systems, building an information-based warehousing management platform, and achieving data communication throughout the entire process of receiving, raw materials and finished products warehousing. By intelligent zoning of warehouses, the inventory status of various materials is clear, various material demand data is updated in real-time, ensuring high-quality and efficient material preparation and delivery processes to meet various production needs.

Standardized support system.

Zinwi Biotech actively cultivates and builds an intelligent professional team to consolidate the talent foundation for intelligent manufacturing. At the same time, it establishes a sound standardized support system, such as clear production processes, visible SOP guidance for operations, strict supervision and inspection mechanisms, and efficient emergency handling measures. Through various standardized work guidelines and methods, it meets customers' large-scale and personalized service requirements, adapting to the more diverse industry development needs of the future.

Currently, Zinwi Biotech's intelligent manufacturing system is empowering its global e-liquid solution. Through the IoT integration of automated production, it realizes full-process data traceability and analysis application, fully ensuring high-quality, high-standard, and high-efficiency output of Zinwi Biotech's e-liquid and providing strong basic security for customer brands to enter the global market.

Standing at a new starting point, Zinwi Biotech's goal remains firm. Focusing on the future, it will continue to lead the transformation and upgrade through intelligent manufacturing, continuously enhance enterprise innovation capabilities, improve digital and intelligent levels, enhance core competitiveness, lead industry development with demonstration effects, and strive to create better e-liquid solutions.

We will contact you as soon as possible