Zinwi Bio Awarded "2025 Shenzhen Green Factory" Title

When the announcement from the Shenzhen Industrial and Information Technology Bureau popped up, our R&D team immediately shared the screenshot in the group chat—right as our waste treatment system was quietly running in the background, efficiently purifying organic exhaust.

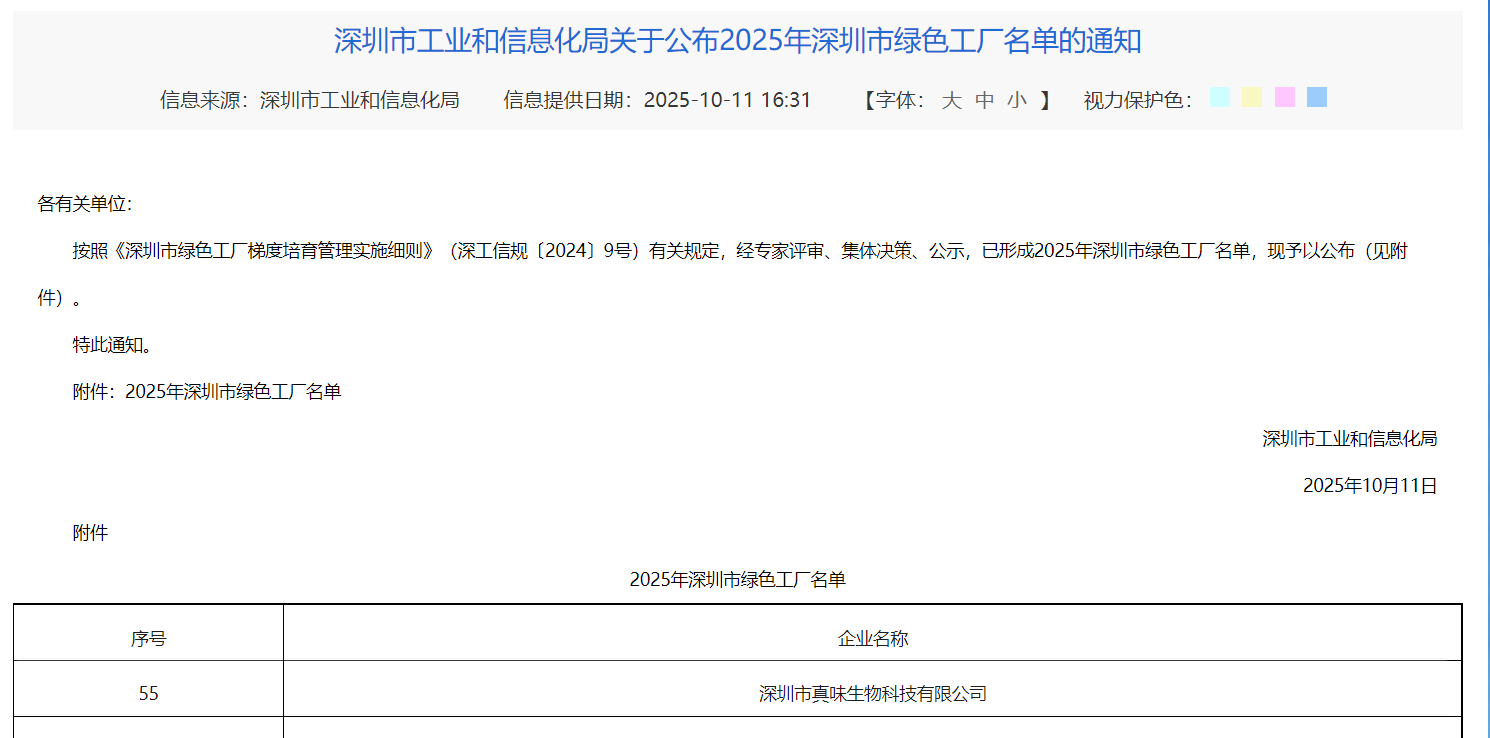

Zinwi Bio has been awarded the "2025 Shenzhen Green Factory" title after passing multiple rounds of strict screening, standing as the only e-liquid company recognized this year. This honor affirms our commitment to "Cleaner Production, Greener Living," and we will continue to engage in environmental collaboration projects, contributing our part to a more sustainable future.

At Zinwi Bio, "green" is not just a buzzword limited to production. It’s a comprehensive commitment that spans from raw materials to end products.

Unlike many companies that focus only on eco-friendly manufacturing, we place strong emphasis on sourcing. Leveraging our global R&D center, we select traceable and sustainable raw materials and have even established an "Ingredient Environmental Rating System" to ensure eco-friendly attributes from the very beginning. We also prioritize a "localized procurement" strategy, partnering with qualified regional suppliers to significantly cut down carbon emissions from long-distance transportation.

In production, over 90% of our equipment is highly efficient and low-consumption. For example, small-scale photovoltaic systems power lighting in common areas, reducing grid electricity use by nearly 10,000 kWh annually. Industrial wastewater from cleaning is stored in specially designed monitored containers and later handled by certified treatment partners. In line with sustainability goals, most of our raw material packaging uses HDPE resin sealed plastic containers, which are fully recyclable and reusable by third-party processors.

During a recent visit, a European client specifically inspected Zinwi’s waste treatment system. Impressed by what they saw, they remarked: “We chose Zinwi not only for great flavors, but for your environmental responsibility—it fully matches our brand values.” Such recognition continues to motivate our green journey.

Our R&D team has also embedded sustainability into e-liquid formulation. After testing hundreds of natural ingredients over more than a year, they successfully introduced low-irritancy solvents into our products. In tobacco-flavored lines, technical processes are applied to reduce harmful substances in extracts. These products are now well-received across global markets—making “green” not just an idea, but a reality.

Our environmental efforts extend across the supply chain. Together with partners, Zinwi has established a "Green Supply Chain Alliance" to share eco-technologies and compliance experience. This initiative has not only earned recognition from leading international clients but also aims to set a reference path for the entire industry.

In addition, Zinwi Bio has established a comprehensive green assurance system. We have conducted ISO 14064 carbon verification for three consecutive years, maintained a CDP rating of "B" for two years, and achieved ISO 50001 Energy Management System certification in April 2025. Across our supply chain, we require ISO 14001 certification as a supplier prerequisite and conduct annual audits. For information management, we utilize real-time monitoring via our supplier management and product traceability systems to track quality data, actively fulfilling our social responsibilities.

This Green Factory honor belongs to every member of the Zinwi team and to the clients who trust us. Moving forward, we will continue to integrate green principles into every step of our development, ensuring that Zinwi leaves its mark on building a sustainable future for the vaping industry.

About the Green Factory Designation

According to the Shenzhen Green Factory Grading Cultivation and Management Implementation Rules, a Green Factory refers to an enterprise that achieves intensive land use, non-hazardous raw materials, clean production, waste resource recovery, and low-carbon energy usage—making it a core unit in green manufacturing. The selection criteria are extremely rigorous, evaluating not only the production process but also the company's comprehensive performance across multiple dimensions, including resource conservation, environmental protection, clean production, and circular economy. Only companies that meet numerous strict standards can receive this honor.

We will contact you as soon as possible